Sea & Sun Organic GmbH is part of the Sea & Sun Technology Group. Sea & Sun Technology GmbH has been an internationally active system provider for marine, energy and environmental technology since 1998. Highly qualified employees and a global sales network ensure the international availability of our products and services. In 2019 and 2023, Sea & Sun Technology was recognized as one of the 100 most innovative companies in Germany.

Building on the core competencies in the areas of aquatic measurement and energy technology and inspired by the growing need for sustainable future technologies, a new, green branch was created with Sea & Sun Organic GmbH. Green stands for the cultivation of microalgae, a rapidly growing market with great economic potential and a wide range of possible applications. The business area includes the production of microalgae biomass, the development of innovative, microalgae-based products and research into sustainable and energy-efficient production systems.

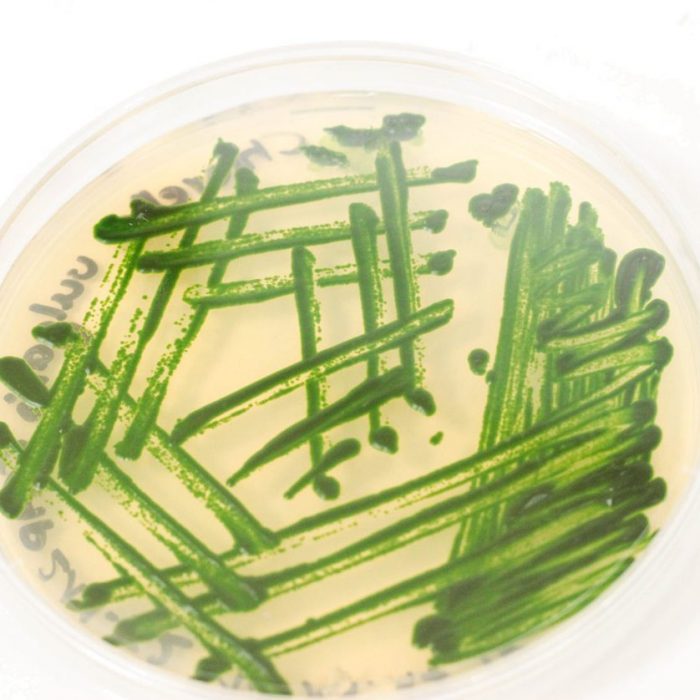

In 2012, we started to set up a pilot-scale microalgae production facility in the heart of Schleswig-Holstein. We acquired a greenhouse with an area of 5,000 m² for this purpose. Since then, various production systems have been tested and further developed, and numerous strains of microalgae have been studied and cultivated. These include, for example, Phaeodactylum, Arthrospira (Spirulina), Porphyridium, Nannochloropsis and Haematococcus. We have deliberately set the bar very high for ourselves: We are continuously researching the optimization of the production process, the algae cultivation facilities and technologies for processing the organisms in order to be able to deliver consistent and outstanding quality at all times.

Our focus is on the production of natural astaxanthin from the blood rain algae (lat. Haematococcus pluvialis). We map the entire upstream and downstream process at our site so that the microalgae are produced and processed directly on site. We carry out all production and processing steps regionally in Germany, thus creating a climate-friendly and fair value chain with the “Made in Germany” label. We offer our products under the registered trademark algenial® in our store.

We work on projects together with partners from research, science and industry and use our international connections to continuously improve our production.

About us

Sea & Sun Organic GmbH is part of the Sea & Sun Technology Group. Sea & Sun Technology GmbH has been an internationally active system provider for marine, energy and environmental technology since 1998. Highly qualified employees and a global sales network ensure the international availability of our products and services. In 2019 and 2023, Sea & Sun Technology was recognized as one of the 100 most innovative companies in Germany.

Building on the core competencies in the areas of aquatic measurement and energy technology and inspired by the growing need for sustainable future technologies, a new, green branch was created with Sea & Sun Organic GmbH. Green stands for the cultivation of microalgae, a rapidly growing market with great economic potential and a wide range of possible applications. The business area includes the production of microalgae biomass, the development of innovative, microalgae-based products and research into sustainable and energy-efficient production systems.

In 2012, we started to set up a pilot-scale microalgae production facility in the heart of Schleswig-Holstein. We acquired a greenhouse with an area of 5,000 m² for this purpose. Since then, various production systems have been tested and further developed, and numerous strains of microalgae have been studied and cultivated. These include, for example, Phaeodactylum, Arthrospira (Spirulina), Porphyridium, Nannochloropsis and Haematococcus. We have deliberately set the bar very high for ourselves: We are continuously researching the optimization of the production process, the algae cultivation facilities and technologies for processing the organisms in order to be able to deliver consistent and outstanding quality at all times.

Our focus is on the production of natural astaxanthin from the blood rain algae (lat. Haematococcus pluvialis). We map the entire upstream and downstream process at our site so that the microalgae are produced and processed directly on site. We carry out all production and processing steps regionally in Germany, thus creating a climate-friendly and fair value chain with the “Made in Germany” label. We offer our products under the registered trademark algenial® in our store.

We work on projects together with partners from research, science and industry and use our international connections to continuously improve our production.

Indoor production facilities

Modern glass tube systems ensure optimal growth rates and stable production conditions. The proven system can be expanded as required, is durable and environmentally friendly. The indoor facilities enable us to produce all year round.

100% Made in Germany

Our production facility is located in the heart of Schleswig-Holstein. The production routes and processing steps are closely linked to our location. This way we stay independent, regional and save costs. All of our products are 100% Made in Germany.

Valuable know-how

We benefit from our many years of experience with various microalgae strains and the associated processing steps. Our equipment ranges from ball mill to spray dryer to centrifuge. Thus, we can carry out a large part of the processing with us and are not dependent on service providers. We also use the technical know-how of Sea & Sun Technology to integrate our production into an automated process. For this we develop our own online measurement and control technology.

Energy efficient

Energy-saving LED technology provides a unique light spectrum and supplies our algae with what they need. In this way, the microorganisms grow optimally and form a particularly large amount of astaxanthin.

Our production

Indoor production facilities

Modern glass tube systems ensure optimal growth rates and stable production conditions. The proven system can be expanded as required, is durable and environmentally friendly. The indoor facilities enable us to produce all year round.

100% Made in Germany

Our production facility is located in the heart of Schleswig-Holstein. The production routes and processing steps are closely linked to our location. This way we stay independent, regional and save costs. All of our products are 100% Made in Germany.

Valuable know-how

We benefit from our many years of process and process engineering experience. Our equipment ranges from ball mill to spray dryer to centrifuge. This means that we can carry out the majority of the processing steps at our location.

Energy efficient

Energy-saving LED technology provides a unique light spectrum and supplies our algae with what they need. In this way, the microorganisms grow optimally and form a particularly large amount of astaxanthin.

Our projects

In addition to our own research, we also work together with partners from science and industry on various projects on the subject of microalgae. We also rely on the know-how of Sea & Sun Technology in the area of sensor technology and have, thanks to years of successful cooperation, an international network to tackle even the most challenging issues. These projects can help us improve our production and develop new processes.

Below you will find information on current and already completed project projects.

AquaHealth

Microalgae Microbiomes – A natural source for the prevention and treatment of aquaculture diseases

In cooperation with:

Technical University Hamburg, University Hamburg, Aalborg University (AAU PLAN, AAU Bio), SINTEF AS

As part of the AquaHealth project, an international consortium of very experienced partners will develop new and innovative instruments and technologies to develop the natural synergy of microalgae and microbial consortia, to develop new bioactive and prebiotic compounds for sustainable use in prevention and discover and validate disease treatment in land-based aquaculture facilities.

The target molecules include urgently needed enzymes that prevent the formation of microbial biofilms (quorum quenching (anti-biofilm) proteins), as well as antiviral natural products such as reverse transcriptase inhibitors. These primary goals are dealt with in seven work packages.

The target molecules include urgently needed enzymes that prevent the formation of microbial biofilms (quorum quenching (anti-biofilm) proteins), as well as antiviral natural products such as reverse transcriptase inhibitors. These primary goals are dealt with in seven work packages.

AstaEx

Development of a new process for the direct extraction of Astaxanthin from Haematococcus pluvialis

In cooperation with:

Technical University of Munich, Privateskinlab

Astaxanthin belongs to the group of carotenoids and is a reddish colorant, which is used in the animal feed industry, the food supplement market and the cosmetics industry. The aim of the cooperation project is the development of a new, cost-effective process for the direct extraction of astaxanthin from the microalgae Haematococcus pluvialis.

ABiRe

Development and implementation of an innovative aquatic-based biorefinery

In cooperation with:

Technical University of Hamburg-Harburg, Polytechnic University of St. Petersburg

The microalgae Chlorella sorokiniana and Lemna minor are cultivated both in open ponds and in closed systems in Germany and Russia. Goals include identifying optimal cultivation conditions, as well as efficient harvesting methods to increase profitability. In order to obtain valuable substances such as proteins, carotenoids or pectin, cost-effective extraction methods are to be developed which are also used in the processing industry. Residual biomass is still used as a sorbent for the treatment of industrial wastewater, especially with regard to heavy metals. At the same time, extraction residues are to be used as a nutrient substrate for anaerobic processes to generate electricity and heat for the process. CO2 arising during the process is used for the phototrophic cultivation of the microalgae.

Cooperations between German and Russian research groups are being created to achieve these goals. The project uses industry experience and links it with the innovation of research and development in both countries.

Cooperations between German and Russian research groups are being created to achieve these goals. The project uses industry experience and links it with the innovation of research and development in both countries.

Offshore project

Microalgae production in offshore/near shore culture

In cooperation with:

Christian-Albrechts-University Kiel, Coastal Research Management

Together with our partners from industry and science, Sea & Sun Technology and our team launched a project on industrial microalgae production at sea in the spring of 2014. Many environmental parameters can support effective ocean production. In addition, there is the possibility of nutrient reduction of eutrophic waters.

Screening project

Screening of cryophilic microalgae species

In cooperation with:

Christian-Albrechts-University Kiel

During the winter months, algae biotechnology is facing increased economic and technical demands in warm temperate and boreal climates. High energy costs for heating and artificial light complicate economically viable production with the common mesophilic algae strains. Despite the limitations defined by the thermodynamic laws and the low levels of sunlight prevailing during the cold season, nature has produced perfectly adapted specialists. These so-called cryophilic or cryotolerant algae show amazing productivity at temperatures around freezing. This ability is evidenced by the appearance of massive algal blooms in the Arctic Ocean or in the snow and meltwater of glaciers.

Together with our colleagues from Sea & Sun Technology, we have worked closely together with Prof. Dr. med. Rüdiger Schulz (Botanical Institute, Christian-Albrechts-University, Kiel) and his colleagues investigated cryotolerant microalgae. The objective was to find biotechnologically relevant strains which, in addition to rapid growth at low temperatures, also achieve high yields of the desired products.

Together with our colleagues from Sea & Sun Technology, we have worked closely together with Prof. Dr. med. Rüdiger Schulz (Botanical Institute, Christian-Albrechts-University, Kiel) and his colleagues investigated cryotolerant microalgae. The objective was to find biotechnologically relevant strains which, in addition to rapid growth at low temperatures, also achieve high yields of the desired products.

Aquaplant Systems

Establishment of cycle-based aquaponics at the Gönnebek site

In cooperation with:

Flensburg University of Applied Sciences, Conviotec GmbH

The overfishing of the seas and the limnic fishing grounds in recent decades has led to global rethinking and an increasing number of land-based aquaculture facilities. However, these require large quantities of high-quality feed and result in a considerable burden on the environment due to their high inorganic wastewater emission. Therefore, it is essential for this industry to find intelligent solutions for cost reduction and sustainability.

Together with our partner, the fish farm Christophersen (Bornhöved), Sea & Sun Technology and our team have combined the fish aquaculture with the microalgae production to close the biogeochemical carbon, nitrogen and phosphate cycle as far as possible. Within this project, we still feed fish with conventional feed with the aim of substituting this feed with algae feed. Similar to the higher plants, algae need sunlight, water, carbon dioxide and inorganic nutrients to grow your growth. Inorganic residues from fish wastewater can be used as a valuable substrate for the cultivation of algae.

Together with our partner, the fish farm Christophersen (Bornhöved), Sea & Sun Technology and our team have combined the fish aquaculture with the microalgae production to close the biogeochemical carbon, nitrogen and phosphate cycle as far as possible. Within this project, we still feed fish with conventional feed with the aim of substituting this feed with algae feed. Similar to the higher plants, algae need sunlight, water, carbon dioxide and inorganic nutrients to grow your growth. Inorganic residues from fish wastewater can be used as a valuable substrate for the cultivation of algae.

Our products

With algenial® we have produced the first food supplement with a natural astaxanthin extract from the blood rain algae (lat. Haematococcus pluvialis). The softgel capsules are packaged in a blister and thus protected from light and oxygen. This ensures long-lasting, high quality. Available in our store.

Go to Shop